Meat and Poultry

packaging solutions for meat & poultry products

meat and poultry collectively form a foundational and diverse category in the culinary world, weaving a tapestry of flavors, textures, and nutritional richness. this encompasses a variety of animal flesh, each possessing unique characteristics, culinary applications, and cultural significance. offering an extensive array of choices that cater to diverse tastes, meat and poultry stand as integral components in culinary traditions globally, whether savored in their purest forms or as vital elements in intricately crafted dishes.

fresh, frozen or processed meat or poultry

your challenge

Beyond their purest forms, meat and poultry take on new dimensions through processing, yielding an array of products such as sausages, deli meats, bacon, and cured meats. These processed delights cater to the convenience and versatility sought by modern consumers.

Yet, the challenge lies in maintaining top-notch quality standards in processed meat production while staying competitive and responsive to market needs. The current trend of packaging fresh and frozen meat to fixed weights reflects efforts by supermarket chains to reduce waste and optimize inventory control, with fixed weight trays playing a pivotal role.

To stay ahead, the meat processing industry must continually innovate to minimize give-away, cut costs, and enhance efficiency. In a landscape where market demands evolve and sustainability takes center stage, adaptability becomes crucial for the enduring success of the meat processing sector.

our solution

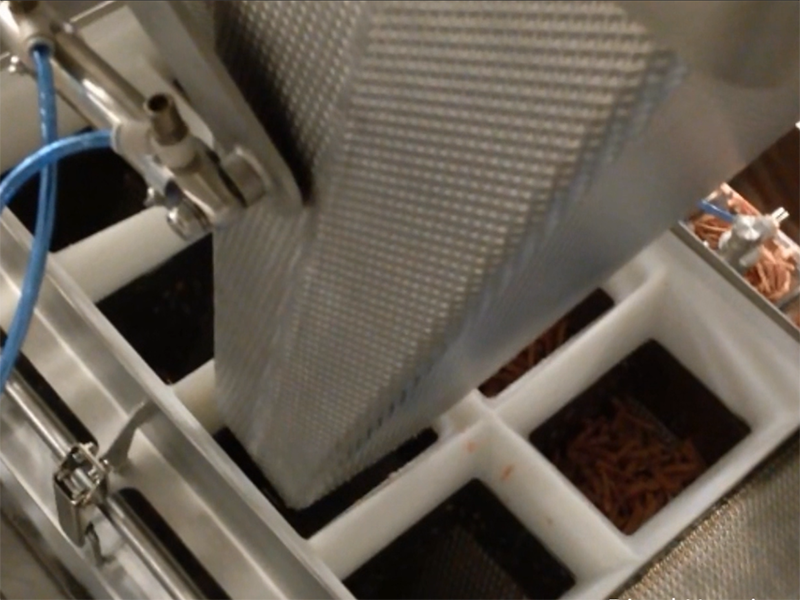

Accurate and precise measurements are paramount when dealing with meat products, particularly in adhering to fixed weight packaging requirements. Our multihead weighers excel in delivering highly accurate portioning, ensuring consistency and compliance with specified weight standards. This capability is crucial for meeting the stringent demands of fixed weight packaging in the meat industry.

In addition to precision, the ability to simultaneously weigh multiple portions is a key feature designed to boost production speed and efficiency. This simultaneous weighing capacity significantly contributes to meeting the high-volume demands of meat processing operations.

Our weighers are engineered to accommodate various packaging styles, ranging from trays in different format to flexible bags and other formats. This adaptability aligns seamlessly with the diverse packaging preferences prevalent in the industry.

tailormade solutions

Given the high value of meat products, minimizing give-aways is a top priority. By precisely weighing and portioning products, our weighers play a vital role in waste reduction, ultimately maximizing yield and optimizing the overall profitability of meat processing operations.

Renowned for our customized customer solutions, we prioritize the careful handling of your valuable meat and poultry products. As a testament to our commitment, we've implemented features like soft drop for several customers, ensuring the gentle treatment of their products throughout the process. Recognizing the diverse nature of meat and meat products in terms of sizes, shapes, and textures, our weighers are designed to handle this. Your satisfaction and the preservation of product integrity are at the core of our tailored solutions.

highest hygiene standard

Due to the direct weighing, self-adjusting and -taring properties of our weighing lines our accuracy is unsurpassed. And our custom-built distribution tools ensure accurate placing in the product receptacle every time, while our new recess-free chassis design makes cleaning and daily hygiene a breeze – a factor that, together with the interchangeable distribution tools, also contributes to our fast pro-duct changeover times.

Hygiene standards in the meat and poultry industry are of the utmost importance, and our infeed systems and weighers are contructed with hygiene in mind. The materials used are selected for ease of cleaning and maintenance, meeting the stringent hygiene requirements essential for ensuring food safety. The commitment to hygiene underscores our dedication to delivering solutions that not only meet but exceed the highest industry standards.

download

For more information download our leaflet for the meat and poultry industry