"we are thrilled with the transformative impact bilwinco’s solution has had on our production operations. the seamless integration of their technology has revolutionized our workflow, from streamlining processes to enhancing efficiency, allowing us to meet growing market demands with ease. enhanced efficiency and easy adaptability to shifting demands, has exceeded our expectations.

their user-friendly interface simplified operations, allowing us to reallocate resources effectively. We highly recommend bilwinco for any organization aiming to optimize production and drive results."

about techno skruv ab

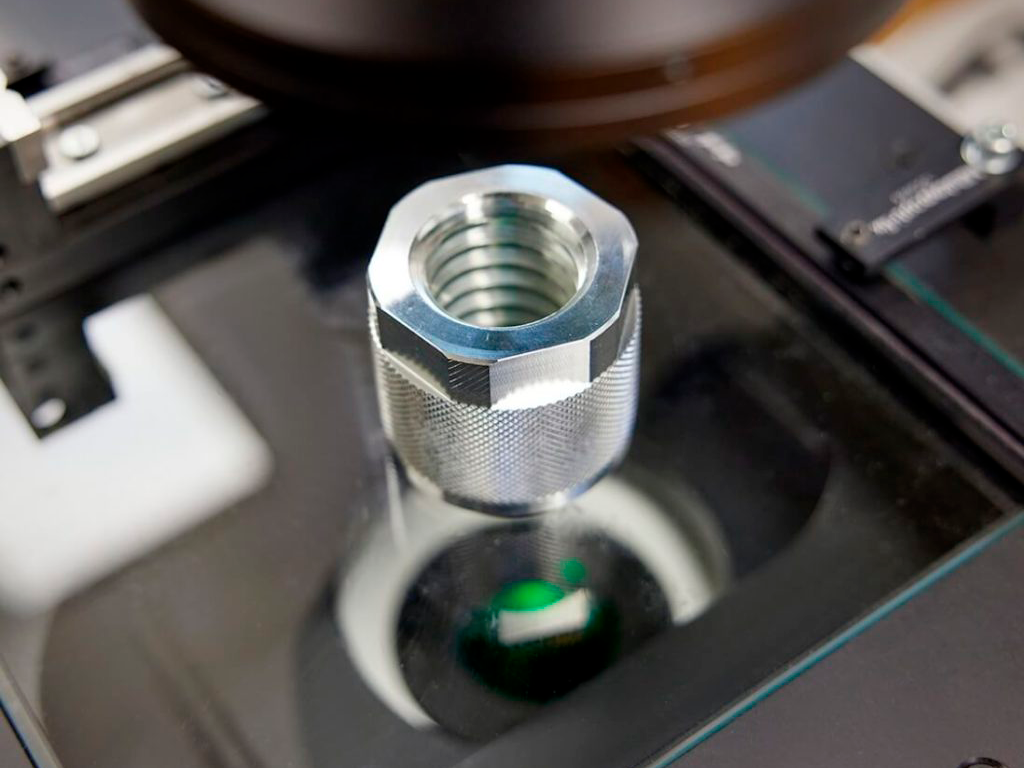

TECHNO SKRUV operates as a trading company and logistics partner, specializing in standard and specialized fastener items for the Swedish engineering industry. Their mission is to

streamline purchasing and supply, ensuring timely delivery of quality components. Serving as a turnkey supplier, they assume comprehensive responsibility and control over the supply chain

of mechanical components, tailored to each customer’s specific needs, while maintaining a high level of service. Committed to delivering world-class quality and customer experience, TECHNO

SKRUV offers solutions developed with a focus on knowledge, quality, and sustainability. With over 30 years of experience, the company has cultivated a top-tier network of suppliers aligned

with their vision of world-class quality. They prioritize delivery reliability, leveraging their extensive experience and expertise in parts and fastener trade to minimize deficiencies and ensure

consistent delivery performance through a meticulously designed logistics solution.

- With heavy-duty products varying in size and shape, a need

for a reliable solution with longevity was essential. All wearing components in Bilwinco systems are easily replaceable. - They have successfully been installing a new linear

weigher solution from BILWINCO. - Portioned products are guided through the PU unit into the

filling funnel and into raised cardboard or plastic trays. - Adjusting to a swiftly expanding market and escalating

product demand, they recognized the need to automate

production procedures effectively while upholding precision.

the challenge

TECHNO SKRUV faced the challenge of adapting to a rapidly expanding market and the growing demand for their products.

They aimed to automate their production processes to meet these demands efficiently while maintaining precision and workflow ease. Given their diverse product range, featuring various sizes and shapes, there arose a necessity for a resilient system capable of accommodating these differences seamlessly. Furthermore, the solution needed to offer flexibility for easy transitions between tasks and operations.

the solution

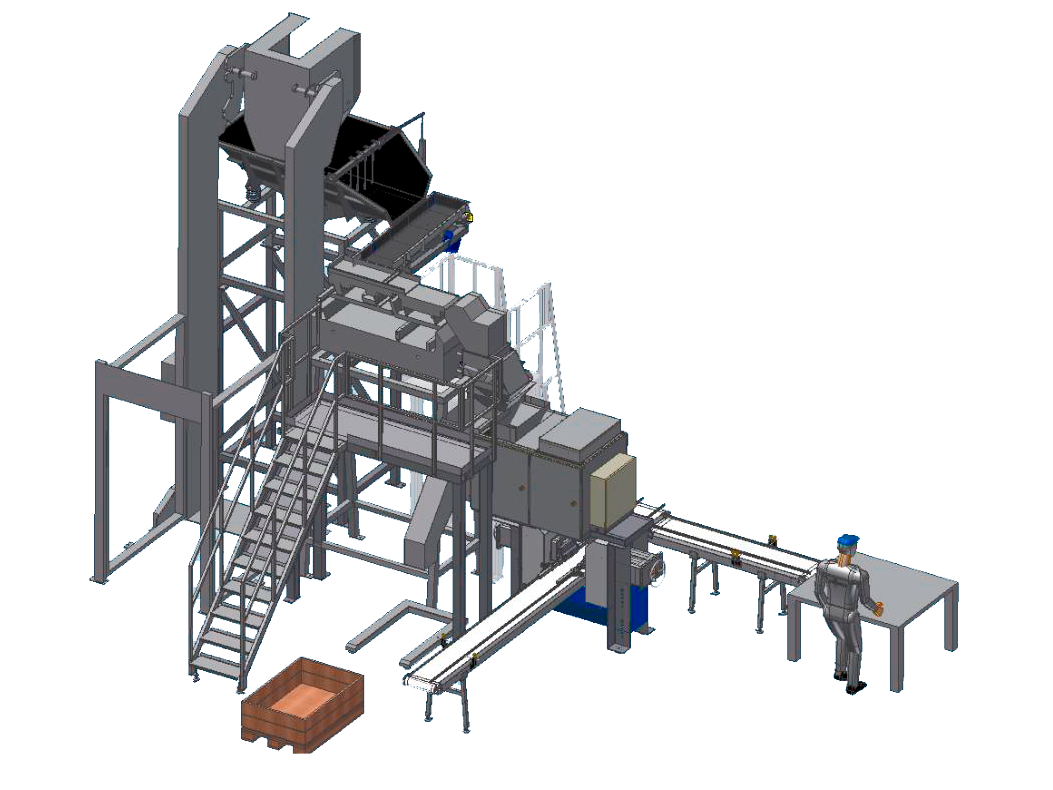

BILWINCO undertook the task of ensuring TECHNO SKRUV’s production goals were met. The solution involved implementing a robust lifting system to handle bulk materials, with a stepwise discharge process. A powerful storage and infeed vibrator ensured a consistent flow of materials to the Linear HW250 weigher. To handle longer items horizontally, the weigher incorporated BILWINCO PU30, an alignment system. Products are fed onto the line from Euro pallets, with a high bin tipper depositing them into the storage vibrator. From there, they are directed to the infeed vibrator and then to the linear weigher, which portioned them accurately using coarse and fine vibrating

channels. Empty cartons or plastic trays were fed into the belt at the inlet end and moved into filling position.

the results

achievements

The solution is designed to streamline workflows and optimize production efficiency. Focus on simplifying complex processes, achieving more with less effort, and significantly reducing operational costs.

optimizations

Automation enhances efficiency by streamlining operations, thereby diminishing the reliance on manual labor and concurrently reducing errors. With its capacity for effortless adjustments in production, automation significantly reduces expenses.

conclusion

The collaboration between TECHNO SKRUV and the BILWINCO

team yielded a flexible solution capable of seamlessly handling

a wide variety of products. BILWINCO not only provided renowned weighing equipment but also supplemented it with an

efficient infeed system. This comprehensive solution empowered

TECHNO SKRUV to optimize their production processes significantly, accommodating various product types, production

shifts, and sizes.

TECHNO SKRUV now operates with enhanced agility and efficiency, setting the stage for continued success and growth in their competitive industry.