"our partnership with bilwinco has been instrumental in overcoming our weighing and packaging challenges at gjuteriteknik. their innovative solutions have not only met but exceeded our expectations in terms of accuracy, reliability, and flexibility. with bilwinco’s equipment in place, we’ve been able to streamline our operations, minimize giveaways, and ensure precision in customer orders. the support and commitment demonstrated by bilwinco have been exceptional, providing us with peace of mind and confidence in our production processes. we highly recommend bilwinco to any company seeking reliable weighing and packaging solutions."

about gjuteriteknik ab

Founded in 1978, Gjuteriteknik has earned recognition as one of Sweden’s fastest-growing companies. Guided by principles of steady growth, long-term thinking, and reinvestment, Gjuteriteknik is led by the vision of brothers Jonas and Peter Abrahamsson. Specializing in die casting with zinc, they aim to provide a comprehensive production process, taking responsibility for their customers’ logistical needs from the design phase onward. Through fully automated processes and state-of-the-art production equipment, the company ensures both flexibility and quality, delivering products punctually to meet client demands. By heavily investing in the integration of advanced machinery, such as packing and dispensing equipment and new CNC machines, as well as establishing a dedicated training facility, the GT Academy course, the company is preparing to meet future demands effectively.

- A recent expansion, adding 1000 m2 of production space, has facilitated a more efficient workflow within the factory.

- Due to the rising demand and expansion of the product range, the production capacity faced significant challenges. Therefore, there arose a need for a new and automated production line to meet these demands efficiently.

- They have successfully been installing a linear weigher from Bilwinco.

- The system is used to portion and package diverse products in bags and carton boxes.

ENHANCING PRODUCTION FLEXIBILITY WITH MOBILE SOLUTIONS

the challenge

Gjuteriteknik consistently enhances its capabilities to meet the growing demands of increased volumes and new projects,

thereby setting new standards for production flow and capacity limits. A recent expansion, adding 1000 m2 to the production

areal, required a more efficient packing and dispensing line, strategically designed to meet the rising demand effectively.

A crucial part of the new production line was a weighing solution that would not only meet its rigorous standards for accuracy, reliability, and cost-effectiveness but also being able to handle diverse products that require high standards

of equipment robustness and reliability.

the solution

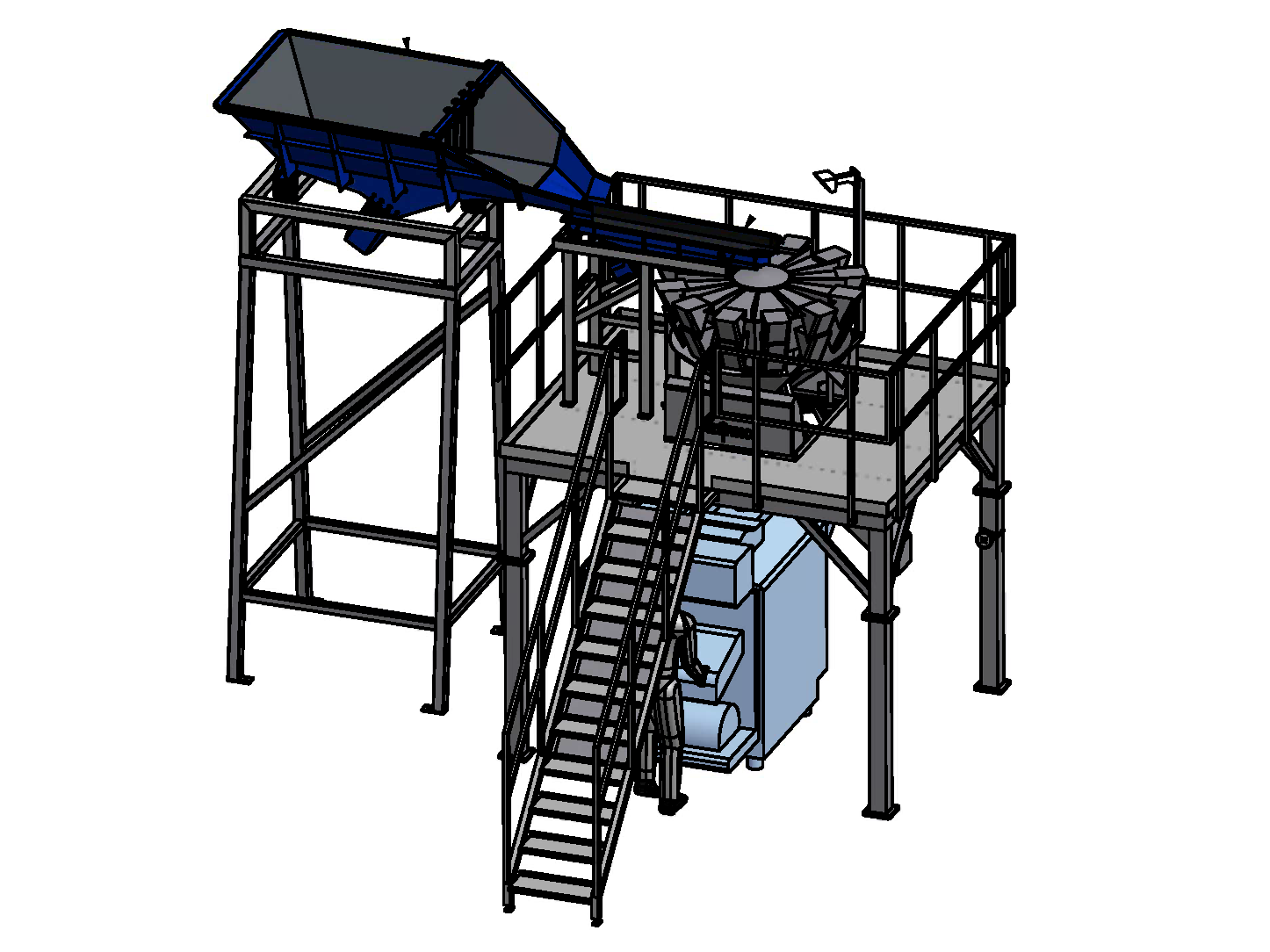

The solution comprises both a linear weigher, the HW250F, ideal for smaller orders necessitating flexible and swift production shifts, and a Multihead weigher, the RW112H, designed for high-volume operations with a continuous flow packaged in bags.

By opting for both types of weighers, the company gains the flexibility to accommodate a diverse product range while minimizing giveaways and ensuring precision in customer orders.

Furthermore, for packaging lines that require precision without extensive setups, Bilwinco’s linear weigher proves to be an ideal choice. Bilwinco provided a comprehensive solution tailored to their specific needs, complete with built-in future-proofing.

the results

impressive roi

An impressive ROI was primarily due to the newfound operational efficiency, which

freed up full-time positions to be allocated to other functions within the production facility.

>0.5% give-away

Gjuteriteknik has gained the flexibility to accommodate a diverse product range while minimizing giveaways - less than 0.5% "give-away".

low tco

Not only does the solution operate reliably and flawlessly, but all wear parts are easily replaceable, significantly lowering the total cost of ownership compared to others.

conclusion

In a close collaborative partnership between Gjuteriteknik and Bilwinco a solution was found to handle a wide range of products seamlessly, thereby optimizing production processes

significantly. Bilwinco did not only deliver renowned weighing equipment but also supplemented it with an infeed system.

This comprehensive system enabled Gjuteriteknik to handle a wide range of products, thereby optimizing our production processes significantly.

Additionally, establishing enduring relationships with reliable backup support and the potential for system updates was of paramount importance in the decision-making process.